Methane Emissions

Methane Transparency and CNX Sustainability

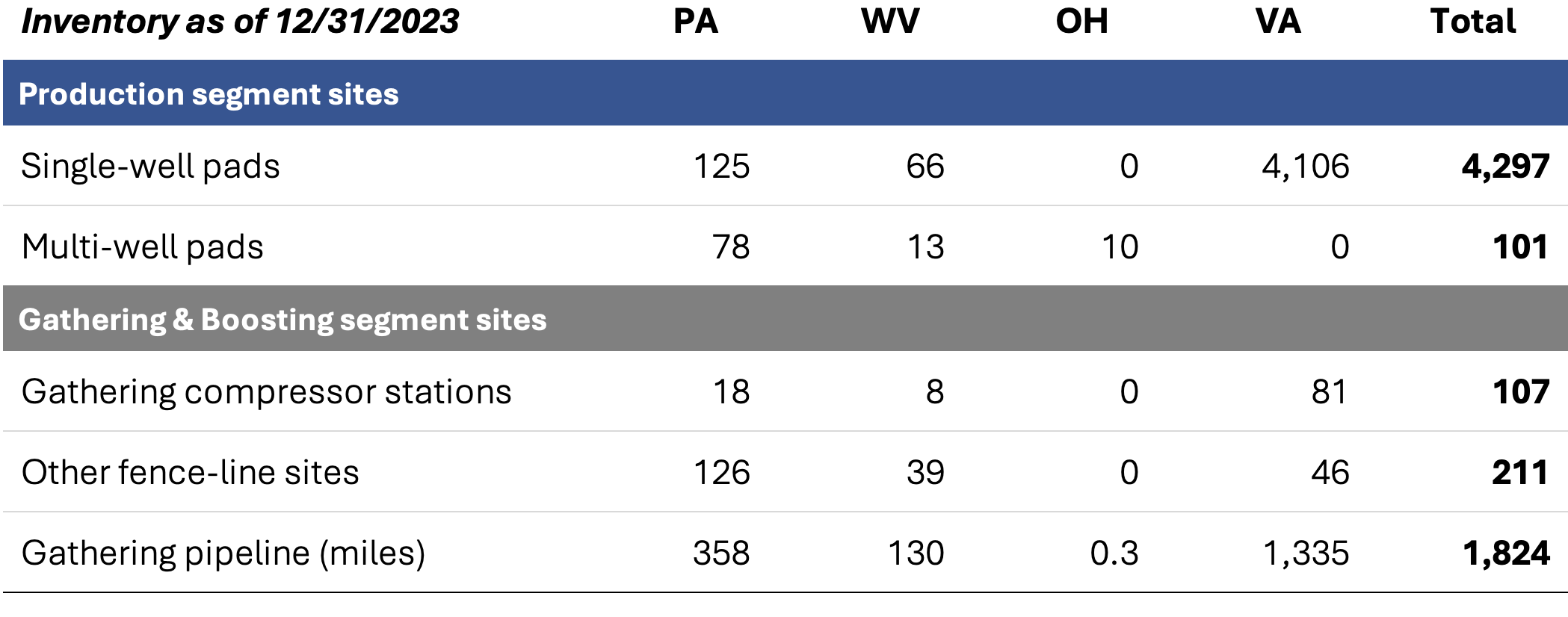

CNX Methane Emissions Asset Inventory

CNX calculates its methane emissions according to the reporting methodologies under the EPA’s Greenhouse Gas Reporting Program (GHGRP) for Petroleum and Natural Gas Systems (subpart W). Current calculation methods can be grouped into five categories: 1) direct emissions measurements; 2) combination of measurement and engineering calculations; 3) engineering calculations; 4) leak detection and use of a leaker emission factor; and 5) population count and population emission factors. EPA developed these emission factors from published empirical data and CNX combines them with site-specific data from our operations. We maintain an inventory of the equipment and/or events that generate methane emissions from our physical locations (sites). Providing transparency around the details of our methane emission sources is fundamental to the credibility of our reported results.

CNX operates within the Production and Gathering and Boosting segments of the natural gas industry. Our operational footprint spans across the Appalachian Basin in parts of Pennsylvania, Ohio, West Virginia, and Virginia. The following tables and charts provide transparency to our reported methane emissions.

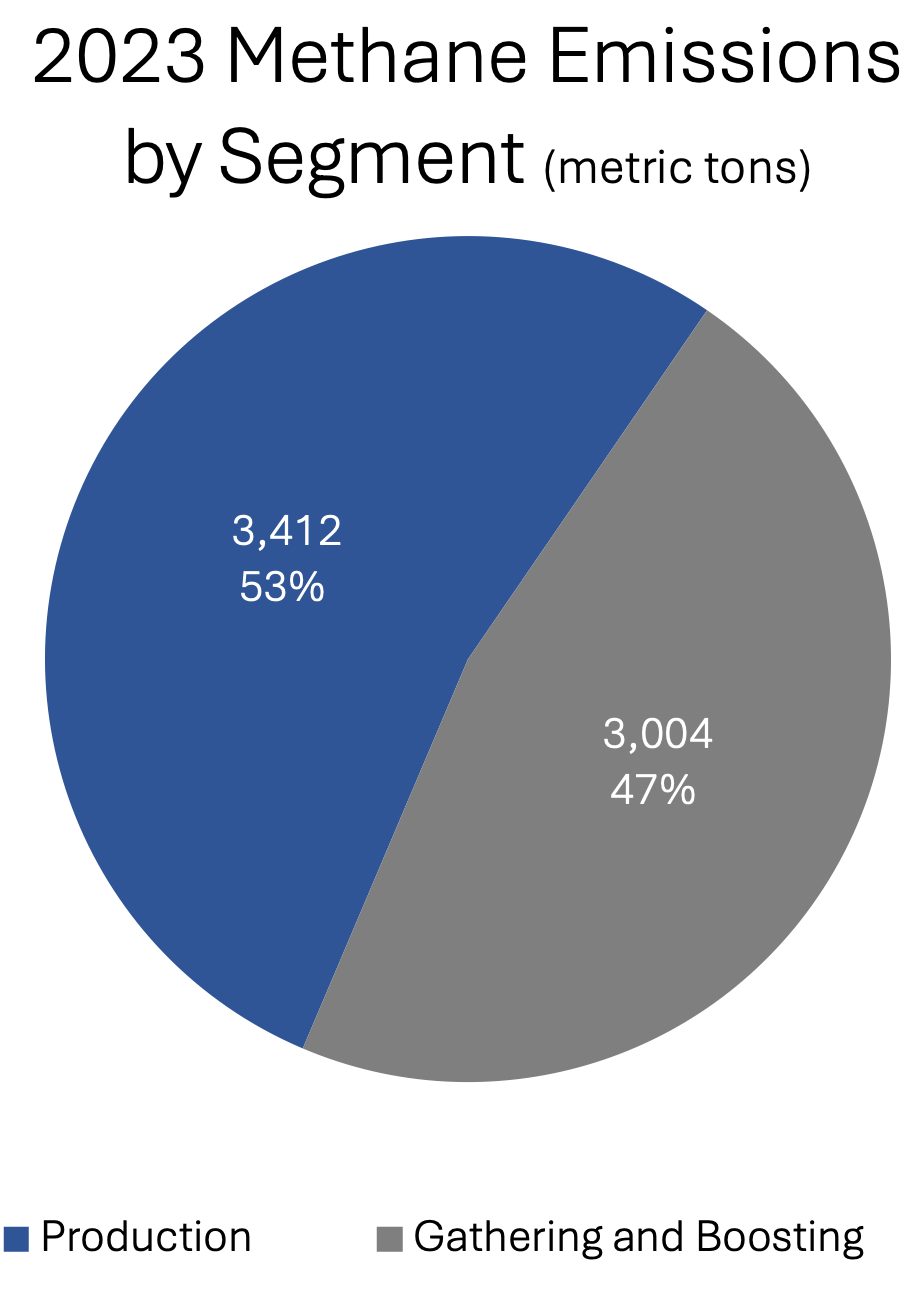

The first table shows the number of physical locations where we conduct our operations for each respective industry segment and state. The pie chart next to this table shows the split of our 2023 methane emissions between these two industry segments. Emissions from our Production segment were slightly more than half of total company emissions, with the majority from this segment coming from the multi-well sites that we operate in Pennsylvania. For the Gathering & Boosting segment, the gathering compressor stations are the primary emitting sites, led by the larger stations, which are also located in Pennsylvania.

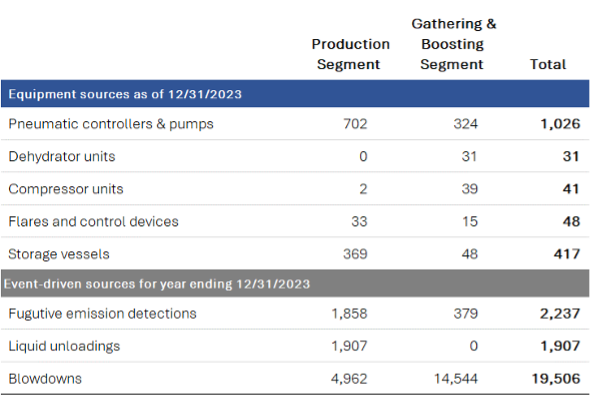

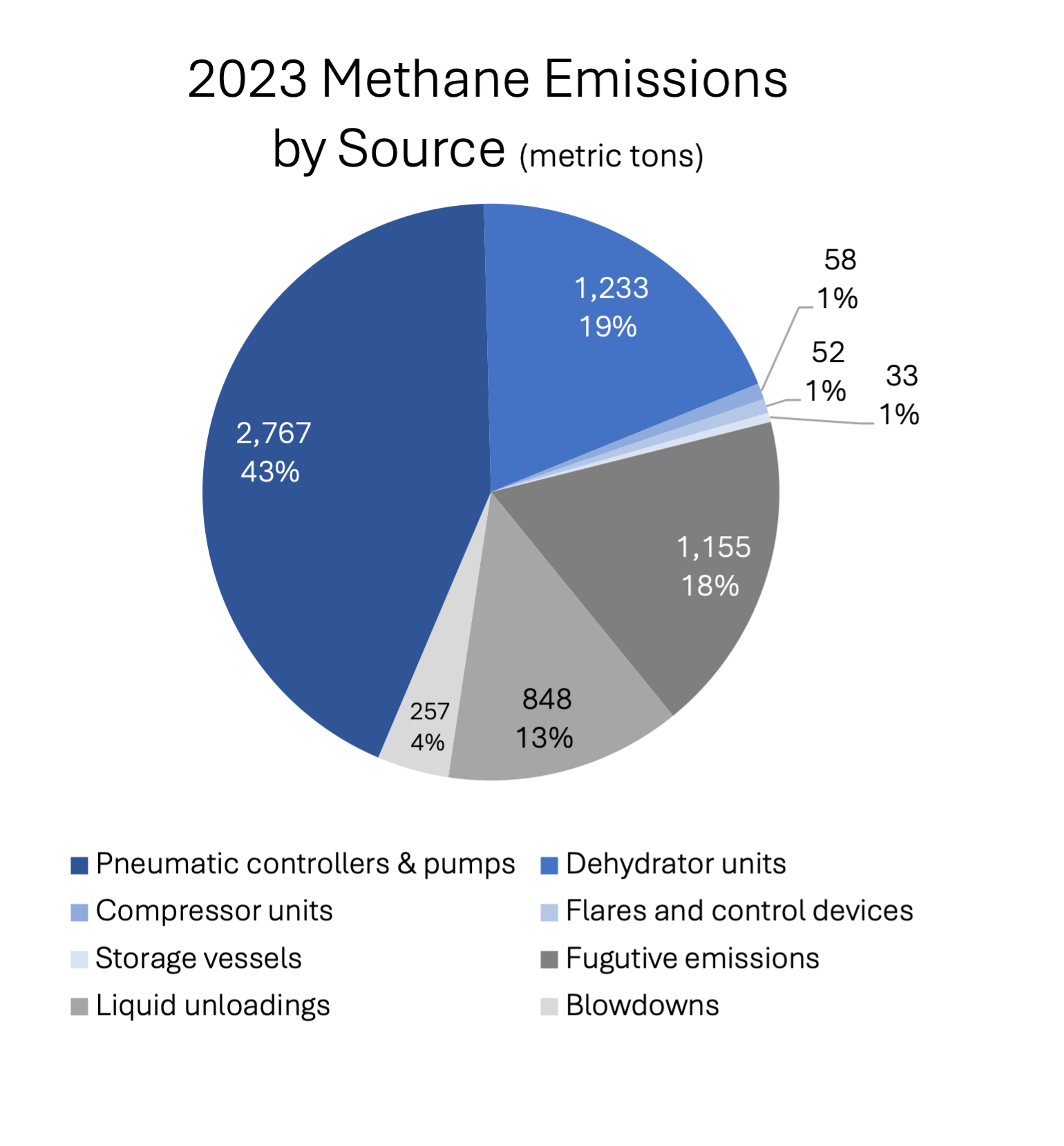

The second table shows the counts of major sources of methane emitting equipment we had in service at the end of 2023 and the number of major event-driven sources of methane emissions we had during the year. Next to the table is a chart that shows the percentage contribution for each of the sources during 2023.

Pneumatic controllers can be categorized based on the emissions pattern of the controller. Some controllers are designed to have the supply-gas provide the required pressure to power the end-device, and the excess amount of gas is emitted. The emissions of this excess gas are referred to as “bleed,” and this bleed occurs continuously. Controllers that operate in this manner are referred to as “continuous bleed” pneumatic controllers. These controllers can be further categorized based on the amount of bleed they are designed to have. Those that have a bleed rate of less than or equal to 6 standard cubic feet per hour (scfh) are referred to as “low bleed,” and those with a bleed rate of greater than 6 scfh are referred to as “high bleed.” Another type of controller is designed to release gas only when the process parameter needs to be adjusted by opening or closing the valve, and there is no vent or bleed of gas to the atmosphere when the valve is stationary. These types of controllers are referred to as “intermittent vent” pneumatic controllers. A third type of controller releases gas to a downstream pipeline instead of the atmosphere. These “closed loop” types of controllers can be used in applications with very low pressure.

Not all pneumatic controllers are natural gas driven. At sites with electricity, electrically powered pneumatic devices or pneumatic controllers using compressed air can be used. As these devices are not driven by pressurized natural gas, they do not emit any natural gas to the atmosphere. At sites without electricity provided through the grid or on-site electricity generation, solar power can be used in some instances.

Dehydrator vent emissions means natural gas and CO2 released from a natural gas dehydrator system absorbent (typically glycol) reboiler or regenerator to the atmosphere or a flare, including stripping natural gas and motive natural gas used in absorbent circulation pumps.

Underground crude oil contains many light hydrocarbon gases in solution. When oil is brought to the surface and processed, many of the dissolved lighter hydrocarbons are removed through a series of high-pressure and low-pressure separators. The oil (or condensate or water) from the separator is then directed to a tank battery where it is stored before being shipped off-site. Some light hydrocarbon gases remain dissolved in the oil, condensate, or water because the separator operates at pressures above atmospheric pressure. These dissolved hydrocarbon gases are released from the liquid as vapors, commonly referred to as flash gas, when stored at atmospheric pressures in the tank batteries. Typically, the larger the operating pressure of the separator, the more flash emissions will occur in the storage stage. The temperature of the liquid may also influence the amount of flash emissions. Lighter crude oils and condensate generally flash more hydrocarbons than heavier crude oils.

In addition to flash gas losses, other hydrocarbons may be emitted from the storage vessels due to working and breathing (or standing) losses. Working losses occur when vapors are displaced due to the emptying and filling of tank batteries. When the liquid level in the tank is lowered, ambient air is drawn into the tank’s headspace. Some hydrocarbons from the liquid will volatilize into the headspace to reach equilibrium with the new headspace gas. When the liquid level in the tank is increased, it will expel the saturated headspace gas into the atmosphere. Breathing losses are the release of gas associated with daily temperature fluctuations when the liquid level remains unchanged. As temperatures drop (or atmospheric pressure increases), gas in the headspace contracts, drawing in ambient air. Again, hydrocarbons volatilize into this new gas due to equilibrium effects. As the temperature rises (or atmospheric pressure falls), the gas in the tank’s headspace expands, expelling a portion of the hydrocarbon-saturated gas. Working losses increase relative to the “turnover rate” (throughput rate divided by the tank capacity) and are typically much greater than breathing losses.

The choice of what liquids unloading technique to employ is based on a well-by-well and reservoir-by-reservoir analysis. To address the complex science and engineering considerations to cover well unloading requirements, many differing technologies, techniques, and practices have been developed to address an individual well’s characteristics to manage liquids and maintain production of the well. At the onset of liquids loading, techniques that rely on the reservoir energy are typically used. Eventually a well’s reservoir energy is not sufficient to remove the liquids from the well and it is necessary to add energy to the well to continue production. Owners and operators can choose from several techniques to remove the liquids, including manual unloading, velocity tubing or velocity strings, beam or rod pumps, electric submergence pumps, intermittent unloading, gas lift (e.g., use of a plunger lift), foam agents and wellhead compression. Each of these methods/procedures removes accumulated liquids and thereby maintains or restores gas production. Although the unloading method employed by an owner or operator can itself be a method that mitigates/eliminates venting of emissions from a liquids unloading event, dictating a particular method to meet a particular well’s unloading needs is a production engineering decision.

Vented emissions means intentional or designed releases of CH4 or CO2 containing natural gas or hydrocarbon gas (not including stationary combustion flue gas), including process designed flow to the atmosphere through seals or vent pipes, equipment blowdown for maintenance, and direct venting of gas used to power equipment (such as pneumatic devices).

CNX’s Emission Reduction Program

At CNX, we are committed to methane emissions reductions. Methane is the primary energy providing compound and salable component in the natural gas that we develop and produce. Our business focuses on capturing methane for sale and, like any other manufacturing business, we design our equipment and operational processes to minimize any product waste/leakage.

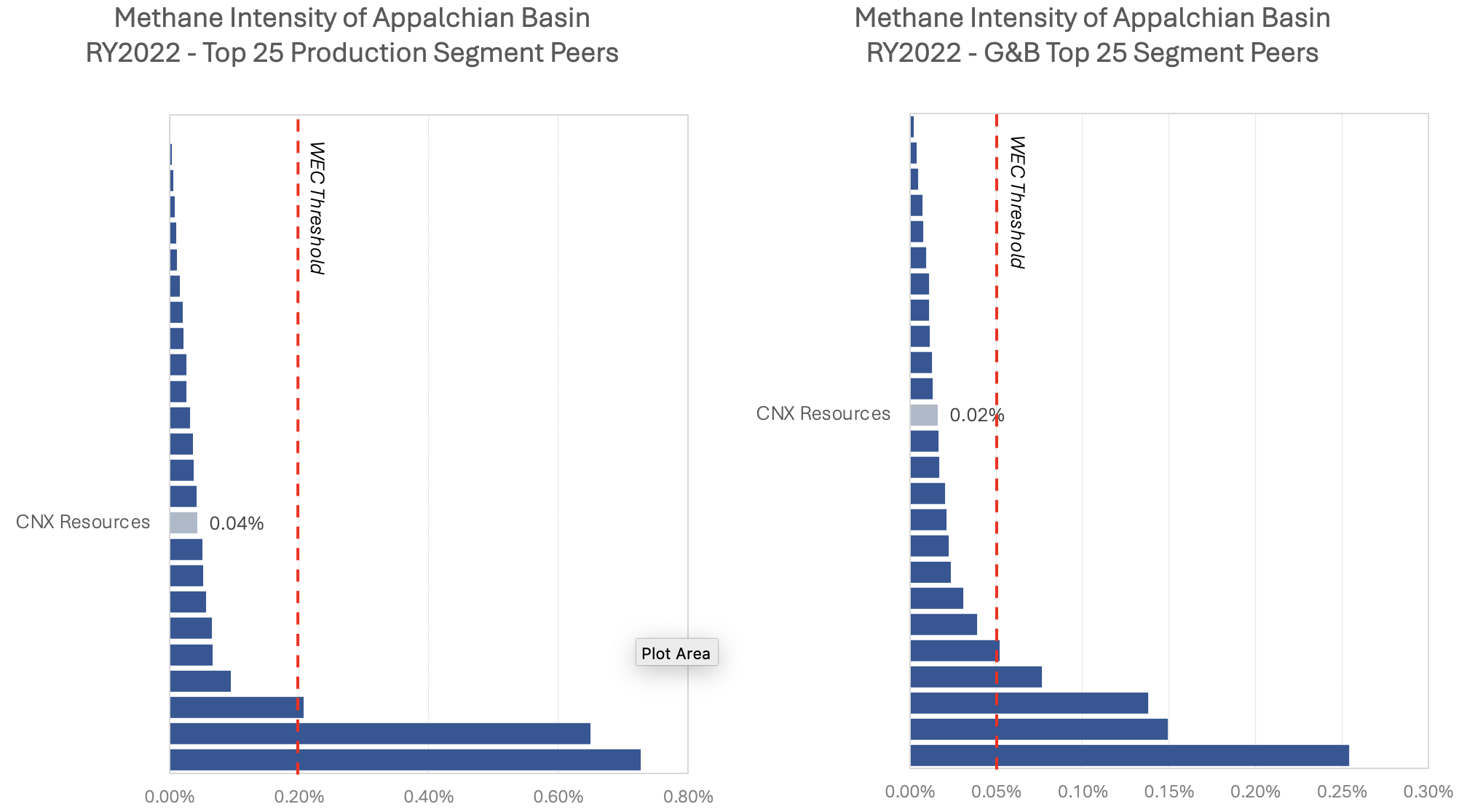

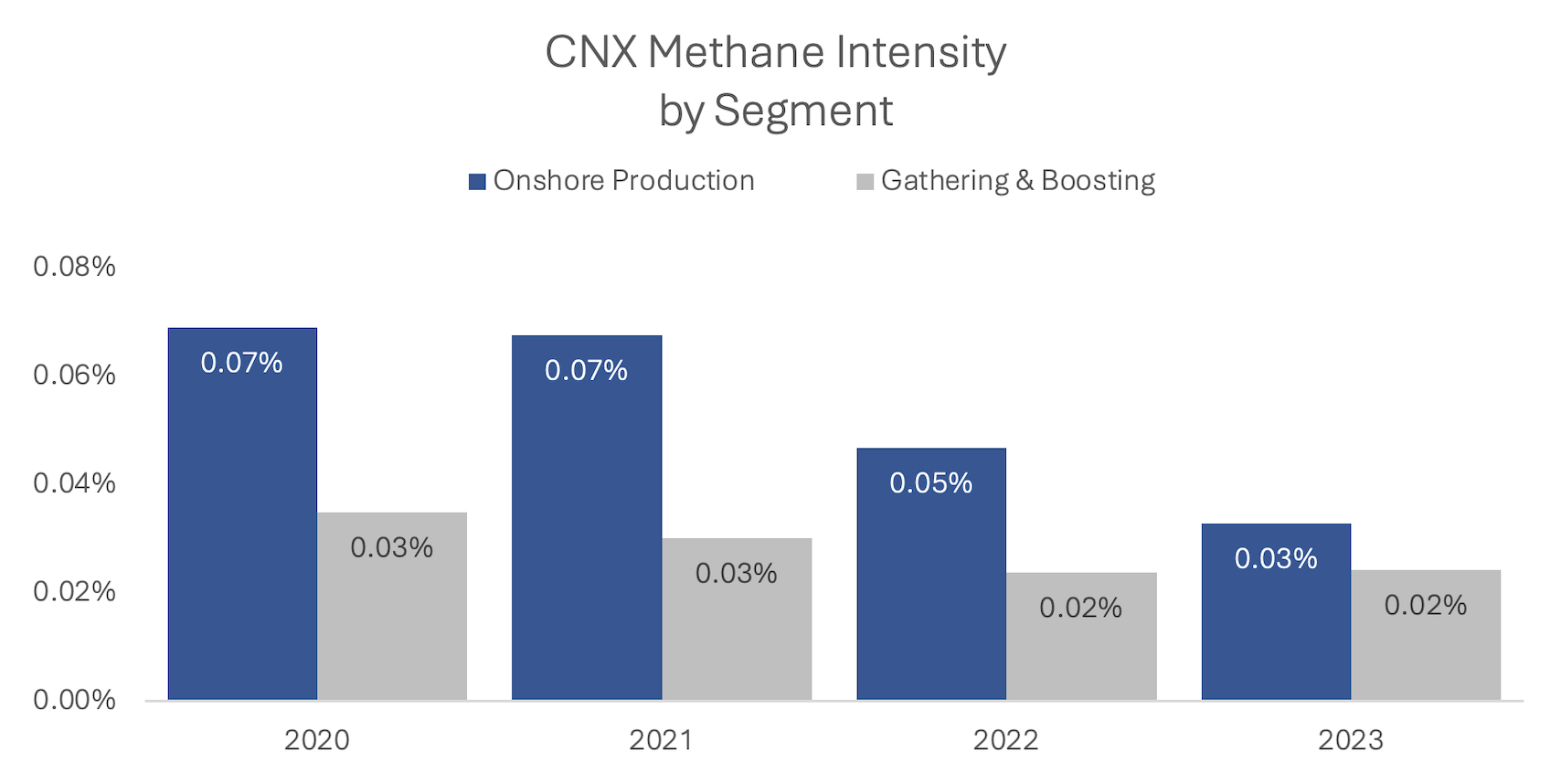

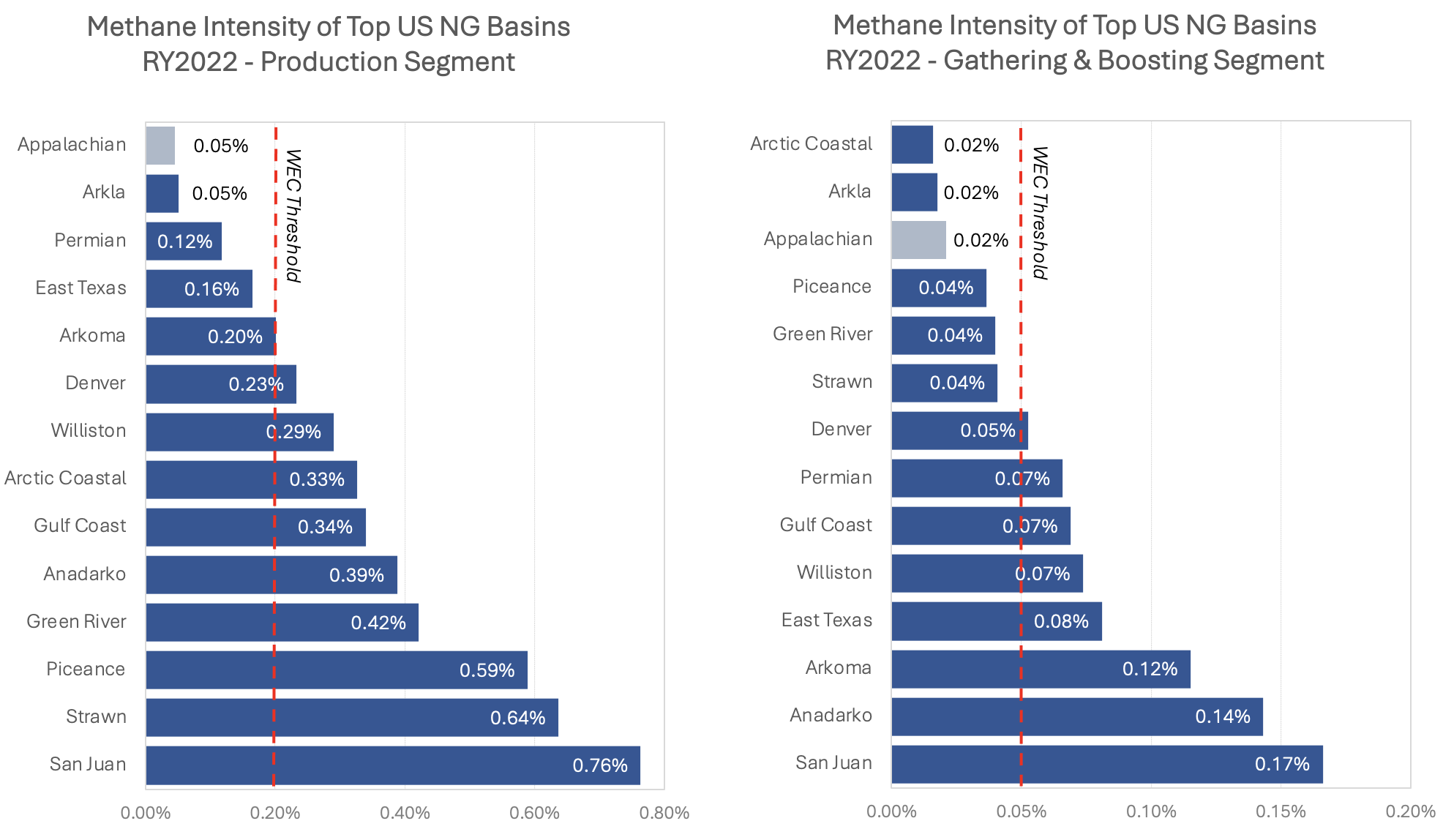

We work diligently to reduce methane emissions through innovative facility design, improvements in operational practices and procedures, advancements in detecting and measuring emissions and improved accuracy in emissions reporting. We measure ourselves against the industry standards that are consistent with meeting the Paris Agreement: (1) the OGCI methane intensity target of being well below 0.2% by 2025; (2) the EPA WEC methane intensity thresholds of 0.2% and 0.05% for the onshore natural gas Production and Gathering & Boosting segments; and (3) the Global Methane Pledge initiative which targets to reduce absolute methane emissions by at least 30 percent from 2020 levels by 2030.

Since 2020, we drastically reduced our methane intensity in both segments of our business, meeting the OGCI target and significantly coming in below the EPA WEC thresholds. Our Production segment has been reduced by 52% during that time to an intensity of 0.03%, while the Gathering & Boosting segment has seen a 31% reduction to 0.02%.

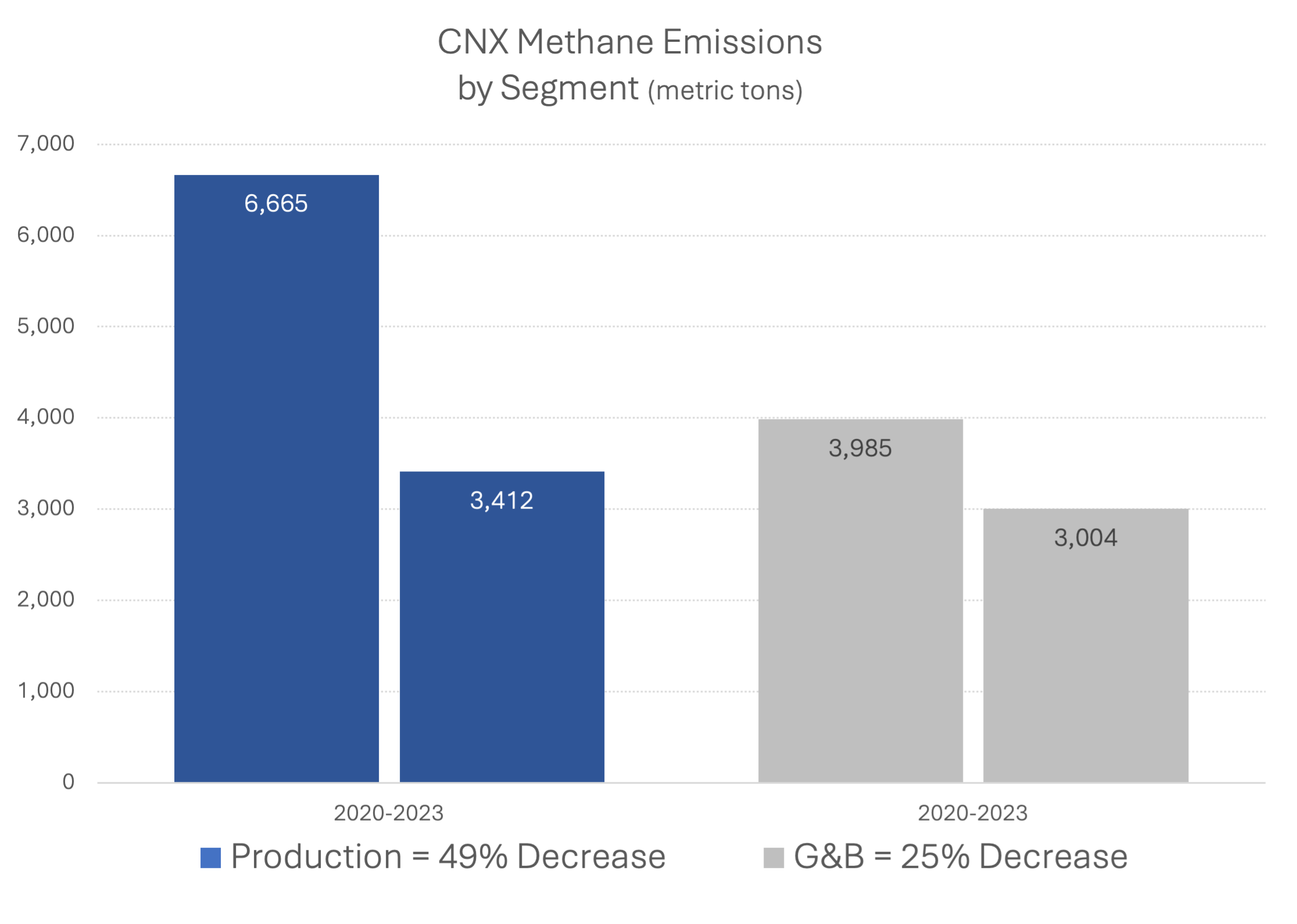

Since 2020, CNX has also reduced its absolute annual methane emissions by 49% and 25% in its Production and Gathering and Boosting segments, respectively. On a company-wide basis, this equates to over 4,200 metric tons, or 40% of reduction to absolute annual emissions – doing our part to help the nation meet its 30% reduction target by 2030 under the Global Methane Pledge initiative.

In 2023, we allocated $7 million of capital investment to methane mitigation efforts. This capital was used to make changes to our pneumatic devices and our liquids unloading procedures that resulted in an annualized methane benefit of over 3,400 metric tons.

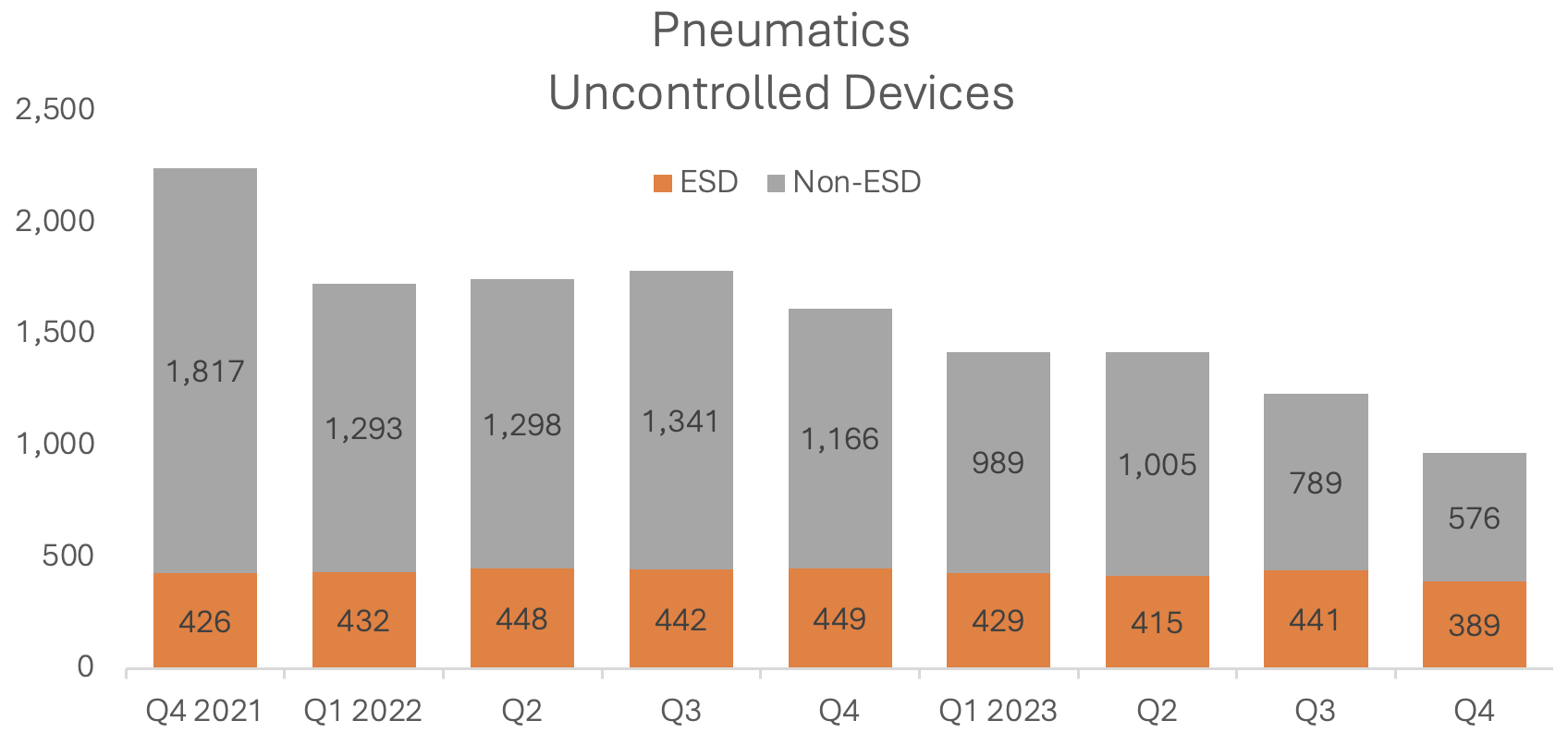

Pneumatic controllers and pumps

As noted in the Asset Inventory section above, pneumatic controllers and pumps make up the largest source category of our methane emitting equipment. These units can be found throughout our operations on well sites and compressor stations. Under the new EPA NSPS/EG regulations, all these units are required to eventually be replaced with zero-emitting units, or to capture and route the methane emissions from the units through a closed vent system to a process. The timing of when these new standards apply differs based on whether the facilities associated with the pneumatics are existing or have been recently constructed, modified, or reconstructed. Generally, for new facilities, the standards go into effect on May 7, 2025, and for existing facilities, an extended timeline for compliance is allowed. An exemption from the rule exists for pneumatics that are used for emergency shutdown (ESD) purposes.

At CNX, we have been voluntarily reducing the methane emissions from our pneumatic devices. Over the two-year period since the end of 2021, we have reduced the number of non-ESD pneumatic devices by nearly 70%. This has been one of the main drivers of the reductions we have seen in our methane intensity and overall methane emissions over the same period.

Liquids unloading from gas wells

Similar to the voluntary efforts we have taken with our pneumatic devices, CNX has also seen significant reductions that relate to voluntary measures taken with the management of our liquids unloading events. Specifically, we have focused on installing plunger lift assistance equipment in wells with a higher probability of liquids unloading events based on data we have collected on events in relation to the age of a well. The installation of the plungers allows for lower amounts of methane to be released during the event by decreasing the volume of the well bore to be vented and increasing the emissions efficiency of the operation through decreased event durations.

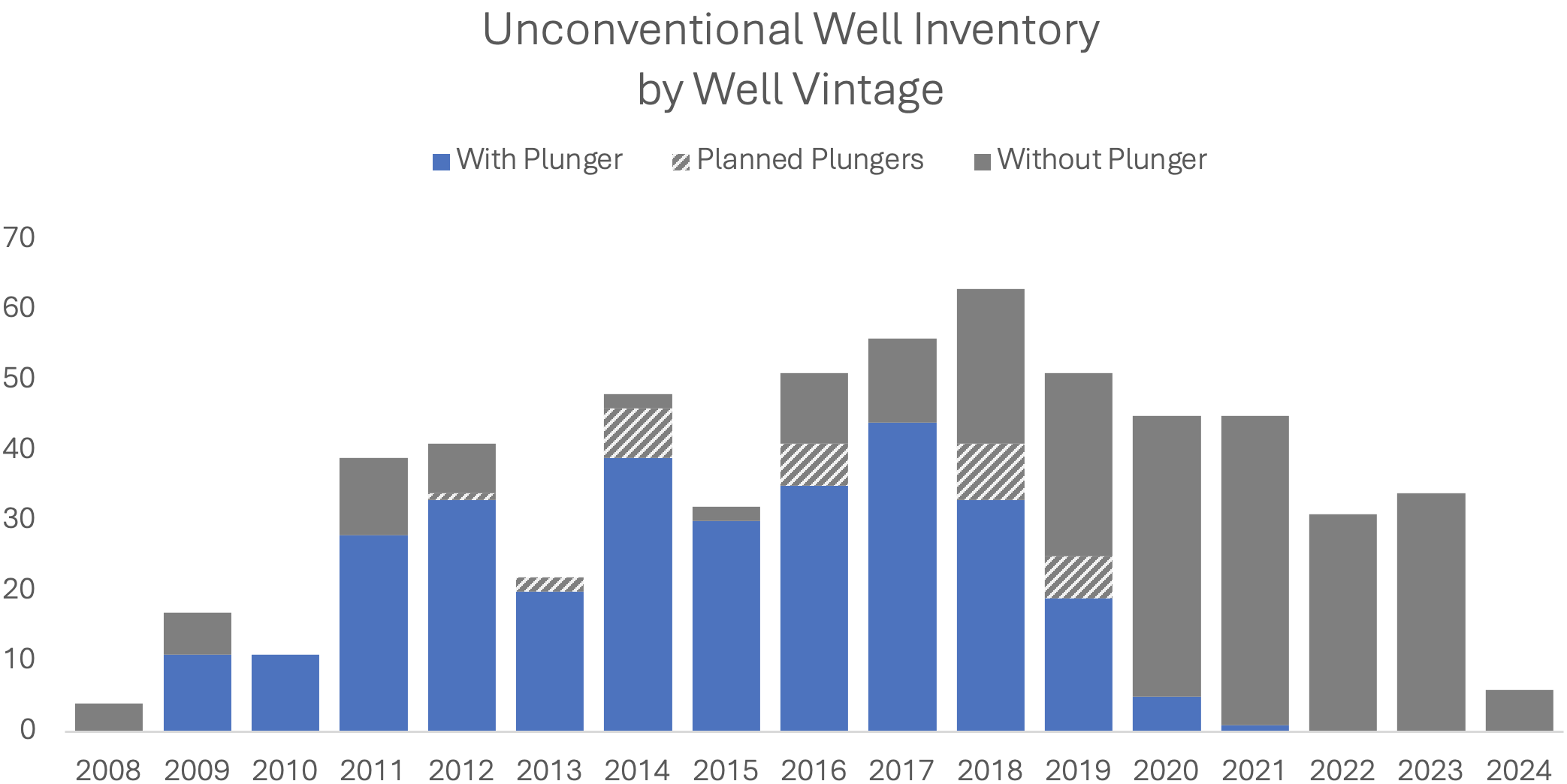

The chart below shows the deployment of the plungers over the population of our major producing unconventional shale well inventory based on the year the well was completed and began delivering gas to sales. The management of these events is another prominent contributor to the methane intensity and overall methane emission reductions we have generated over the past several years.

2024 plan

- Continue routine leak monitoring at all well sites and compressor stations;

- Eliminate or minimize emissions from common pieces of equipment used in our operations such as process controllers, pumps, and storage tanks;

- Monitor flares and other combustion control devices during routine leaks monitoring surveys – ensuring that these control devices are operating properly on a continuous basis;

- Reduce storage vessels (tanks) emissions by 95 percent; and

- Use best management practices to minimize or eliminate venting of emissions from gas well liquids unloading.

Emissions Monitoring

Leak Detection and Repair Program

CNX's leak detection and repair (LDAR) program is designed to mitigate methane emissions related to unintended releases. Its effectiveness is based on how accurately we can identify the source and limit the duration of a leak. Optimal identification requires frequent deployment of leak detection technology across all potential sources, while limiting duration is measured by (1) how quickly new leaks can be found and (2) how quickly the leak is repaired after it is found. The following set of slides will be refreshed monthly with current data to provide transparency around the effectiveness of our LDAR program. The Leak Details slide provides all the significant information that we collect for each of the leaks we find and allows the user to see this data in tabular form by right clicking the chart.CNX currently deploys the following site surveying techniques to monitor for leaks:

- Ground-based component-level surveys with handheld optical gas imaging (OGI) cameras;

- Aerial flyover surveys with remote gas sensing technology fixated to aircraft; and

- Ground-based continuous stationary monitoring systems.

OGI surveys

As prescribed by EPA regulations, we conduct quarterly leak detection surveys with an OGI camera at all major CNX well sites and compressor stations. Additionally, we voluntarily conduct quarterly OGI surveys across sites that have less frequent requirements. These surveys cover any component on the site that has the potential to emit fugitive emissions of methane, such as valves, connectors, pressure relief devices, open-ended lines, flanges, covers and closed vent systems, thief hatches or other openings on a storage vessel, compressors, instruments, meters, and yard piping.

If a leak is detected during the survey, we utilize proprietary software, developed in-house, to provide automated repair work order notifications and leak detection tracking. This process allows for timely repair of leaks well within regulatory requirements.

Advanced Methane Detection Surveys

We complement our regulatorily required OGI surveys with multiple detection technologies in combination with one another to focus and optimize our methane mitigation efforts. These alternative advanced methane detection surveys range from aerial flyovers using remote sensing technology, that screen hundreds of sites in a single deployment, to on-site sensor networks that deliver continuous real-time monitoring.

We perform quarterly aerial flyovers of our operating areas through our membership in the Appalachia Methane Initiative (AMI), which is a proactive, first-of-its-kind basin-wide initiative designed to further enhance methane emissions monitoring and, ultimately, facilitate additional methane emissions reductions in the Appalachian Basin.We utilize Bridger Photonics and ChampionX for methane surveys, SLR International for strategic consulting, and the Energy Emissions Modeling and Data Lab – a consortium at University of Texas at Austin that also includes Colorado State University and the Colorado School of Mines – to lead the scientific analysis.

As part of the AMI 2024 flight campaign, 229 of our major Production and Gathering & Boosting sites will be surveyed on a quarterly basis. By leveraging coordinated aerial surveys alongside on-site monitoring technology, advanced reporting frameworks, and operational data, we are able to detect and determine the causes of various methane emissions.

CNX has Project Canary ground monitoring sensors at our RichHill production facilities that represent nearly one third of the gas we sell to market. Project Canary delivers auditable and verifiable environmental attributes for Responsibly Sourced Gas and publishes those results to a registry that offers transparency to stakeholders. We have received Project Canary’s highest rating (platinum) for those sites. Obtaining the platinum level rating entails undergoing an environmental assessment, utilizing continuous monitoring technology, and quantification of methane emissions intensity.

In addition to the Project Canary sensors that we have been using for two years, CNX is adding fixed methane monitoring cameras at all of our RT sites. These cameras are provided by CleanConnect.ai who provides visual automation for oil and gas, including gas leak detections and methane measurement.

For these supplemental surveying techniques, we have developed a process where we investigate all methane detections. Any detection that is determined to be a leak is logged into our LDAR program where it is tracked to timely repair. For methane detections that are from normal operational releases, we collect all relevant quantification information and reconcile to the methodologies used for our emission reporting obligations.

Methane Performance and Intensity Standards for the U.S. Oil & Gas Industry

Led by a group of CEOs from the major energy companies, the oil and gas industry also responded to the global climate change concerns by establishing the Oil and Gas Climate Initiative (OGCI) in 2014. Their mission is to work collaboratively to reduce GHG emissions consistent with the Paris Agreement. Reducing methane emissions from oil and gas operations was identified by OGCI as one of the quickest ways to help meet the Paris Agreement objectives and became one of its top priorities. In 2018, OGCI created its first methane intensity target and currently aims to be well below 0.20% by 2025 for upstream natural gas producers. Methane intensity is defined as the amount of methane that is emitted as a percentage of marketed natural gas production.2 For the year ending 2023, CNX’s upstream operations methane intensity was over 80% below the OGCI 0.20% target.

In 2021, the United States, the European Union, and other nations launched the Global Methane Pledge initiative to reduce absolute global methane emissions and keep the Paris Agreement goal of limiting warming to 1.5°C within reach. A total of over 100 countries representing 70% of the global economy and nearly half of anthropogenic methane emissions have now signed onto the pledge. Countries joining the Global Methane Pledge commit to a collective goal of reducing absolute global methane emissions by at least 30 percent from 2020 levels by 2030. Participants to the Pledge also commit to moving towards using the highest standards in inventory methodologies, as well as working to continuously improve the accuracy, transparency, consistency, comparability, and completeness of national greenhouse gas inventory reporting under the Paris Agreement.3

These international and industry initiatives form the basis of the methane emissions performance standards that CNX measures itself against. The next section describes the recent U.S. laws and regulations that have also been enacted to support these commitments, creating legal compliance obligations to deliver the methane intensity levels and absolute methane reductions needed to meet the Paris Agreement climate objectives.

1 The Paris Agreement | UNFCCC

2 Oil and Gas Climate Initiative sets first collective methane target for member companies | OGCI

3 Homepage | Global Methane Pledge

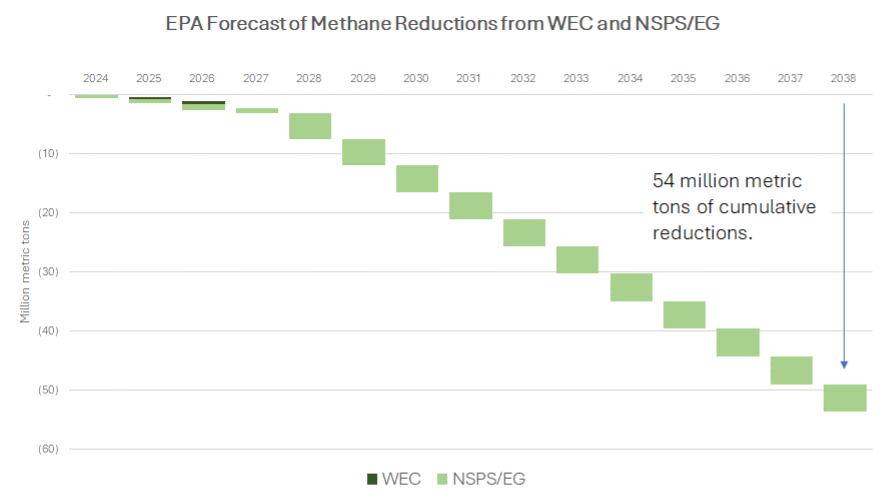

Congress designed the WEC to work in tandem with other EPA regulations, the most significant of which was finalized in March 2024 and is known as the Standards of Performance for New, Reconstructed, and Modified Sources and Emissions Guidelines for Existing Sources: Oil and Natural Gas Sector Climate Review. This regulation provides operating standards for many of the major sources of methane emissions in the U.S. oil and natural gas industry and is designed to achieve absolute emissions reductions that are aligned with those committed to in the Global Methane Pledge (30% reduction of 2020 levels by 2030). Because the application of the rule is based on whether the emission source relates to a newly constructed or existing facility, it is often referred to as the New Source Performance Standards (NSPS) and Emissions Guidelines for Existing Sources (EG), (together, NSPS/EG). The NSPS portion of the regulation is to be administered by the EPA and takes effect immediately. The EG portion on the other hand, is a presumptive standard that is designed to inform states in the development, submittal, and implementation of their own methane emissions regulation plan. The EPA therefore assumes that it will take longer to go into effect and doesn’t expect to see impacts from the EG until 2028.

The WEC provides an incentive for the early adoption of methane emission reduction practices and technologies for sources at existing facilities such as those required under the EG. The sooner facilities adopt the methodologies and technologies required in those rules, the lower their assessed WEC; at full implementation of those rules, the EPA expects many of the WEC-affected facilities will be below the WEC emissions thresholds.

The EPA estimates that the WEC will result in cumulative emissions reductions of 960 thousand metric tons of methane and $1.5 billion (present value) of net climate benefits over the 2024 to 2035 period.

The EPA estimates that the NSPS/EG will result in cumulative emissions reductions of 53 million metric tons of methane and $97.0 billion of present value of net climate benefits over the 2024 to 2038 period.

Together, the WEC and NSPS/EG are projected to reduce U.S. emissions by nearly 80%, significantly exceeding the 30% targeted by the Global Methane Pledge initiative that is needed to stay aligned with the Paris Agreement goal of limiting global warming to 1.5°C.

4 For more information on the different oil and natural gas industry segments, see GHGRP and the Oil and Gas Industry | US EPA.

Drilling down to the individual operators within the Appalachian Basin, the methane intensities of most of the largest producers and gatherers (including CNX) are well below the WEC thresholds.

Drilling down to the individual operators within the Appalachian Basin, the methane intensities of most of the largest producers and gatherers (including CNX) are well below the WEC thresholds.