CNX undertakes thorough efforts to ensure that the additives that we use in our processes do not impact surface water or residential drinking aquifers. Under current guidelines and industry practice, operators collect one groundwater sample to determine baseline conditions. CNX is committing to a much more comprehensive water quality monitoring program, whereby we will collect four quarterly water samples before drilling commences as well as four quarterly water samples post development.

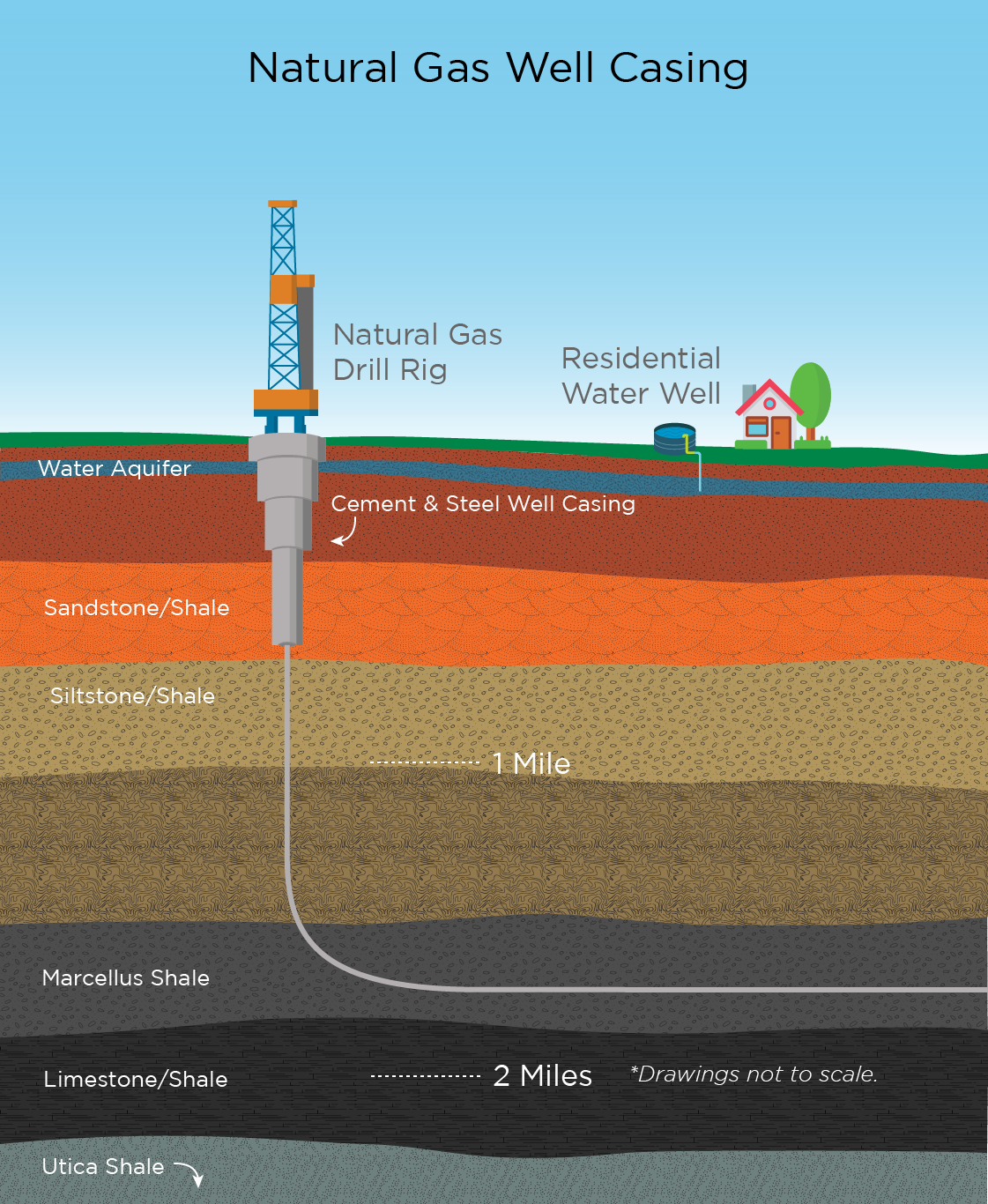

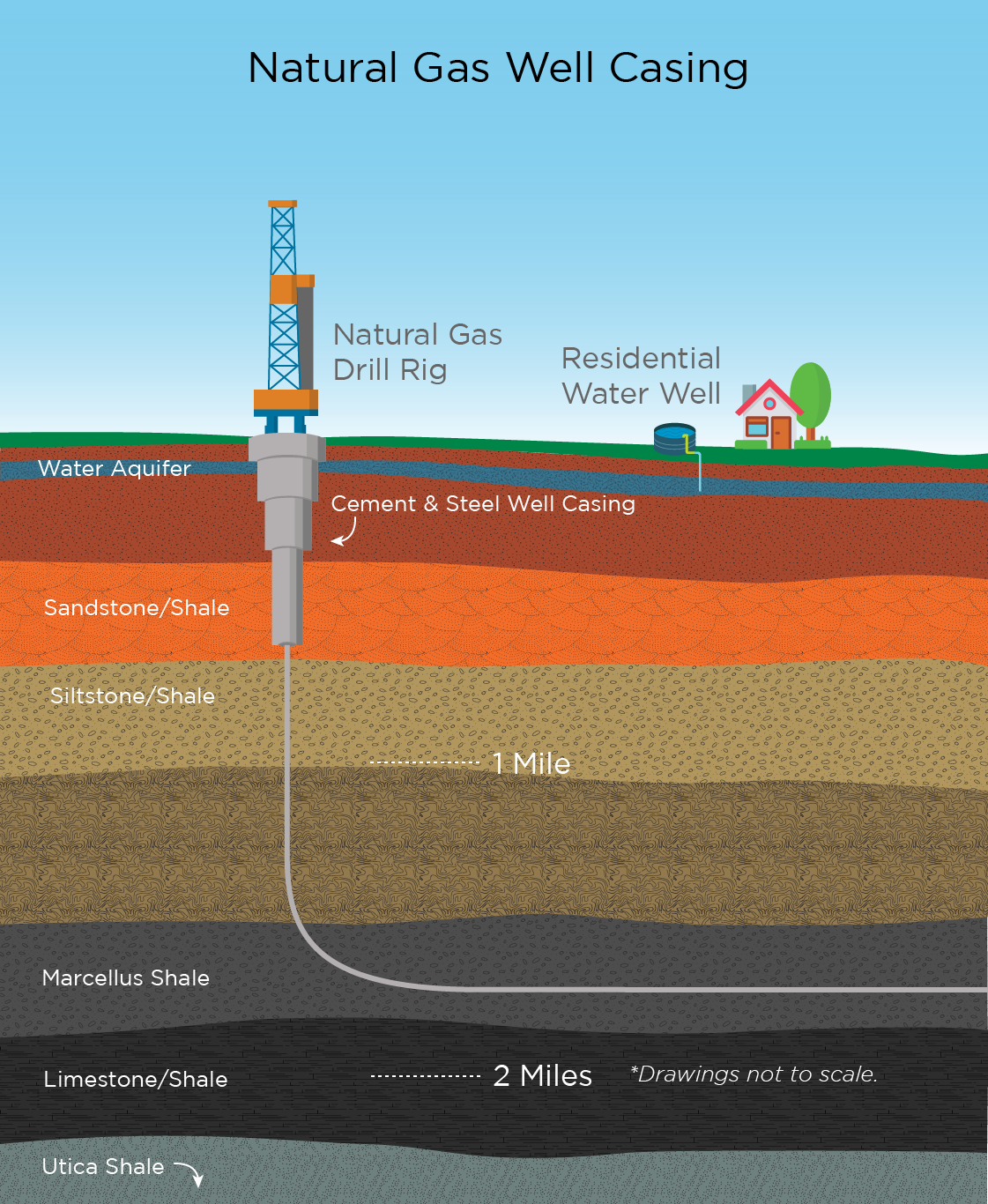

This series of pre- and post-drilling groundwater and nearby surface water sample collection will provide water quality data over time and confirm that the multiple layers of steel casing protect residential drinking water aquifers (groundwater) and surface water. Collection of one groundwater sample does not adequately establish the needed range of chemical concentrations that are naturally occurring in the area (baseline conditions). In order to provide for a thorough and comprehensive understanding of baseline conditions, CNX will analyze four quarters of pre- and four quarters of post- development conditions. While all wells in our current development plan will not have adequate time to establish this pre-drill baseline, we will be phasing in this multi-quarter concept over the next 2 years.

CNX will rely on indicator parameters to alert to any potential water quality anomalies. For example, total dissolved solids (TDS) found in fluids CNX utilizes for hydraulic fracturing operations is significantly higher than that which is detected in drinking water aquifers. TDS along with other elements such as chloride, sodium, sulfate, and other metals serve as common indicators to alert to potential groundwater impacts. These constituents, along with other selected parameters, are monitored and if these indicators differ unexpectedly from pre-drill (baseline) conditions further evaluation may be warranted. It's important to note that changes in these indicator parameters do not always imply connection to deep production water from hydraulic fracturing. Water well operations and water table fluctuations may contribute to observed increases, and the series of pre-drill baseline analyses will help inform on these natural fluctuations.

Private residential drinking water well/spring owners will be given the opportunity to opt in to the (blind) public disclosure. At a minimum, all residential samples collected and analyzed will be provided to the source owner.