Drilling and Hydraulic Fracturing Additives

CNX works diligently to protect water quality before, during, and after drilling and hydraulic fracturing activity by completing pre and post development water sampling and analysis and collaborating with landowners and state regulatory agencies.

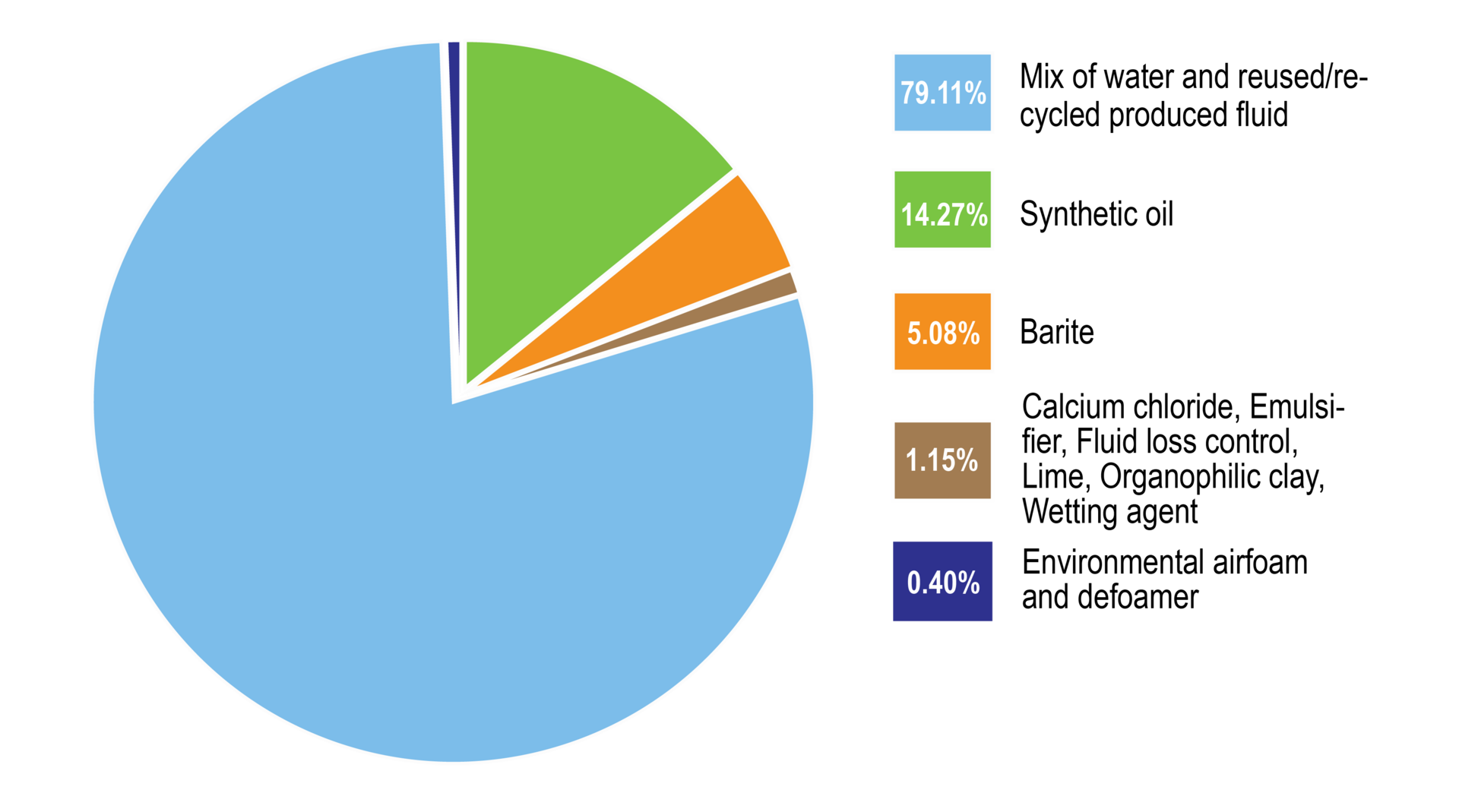

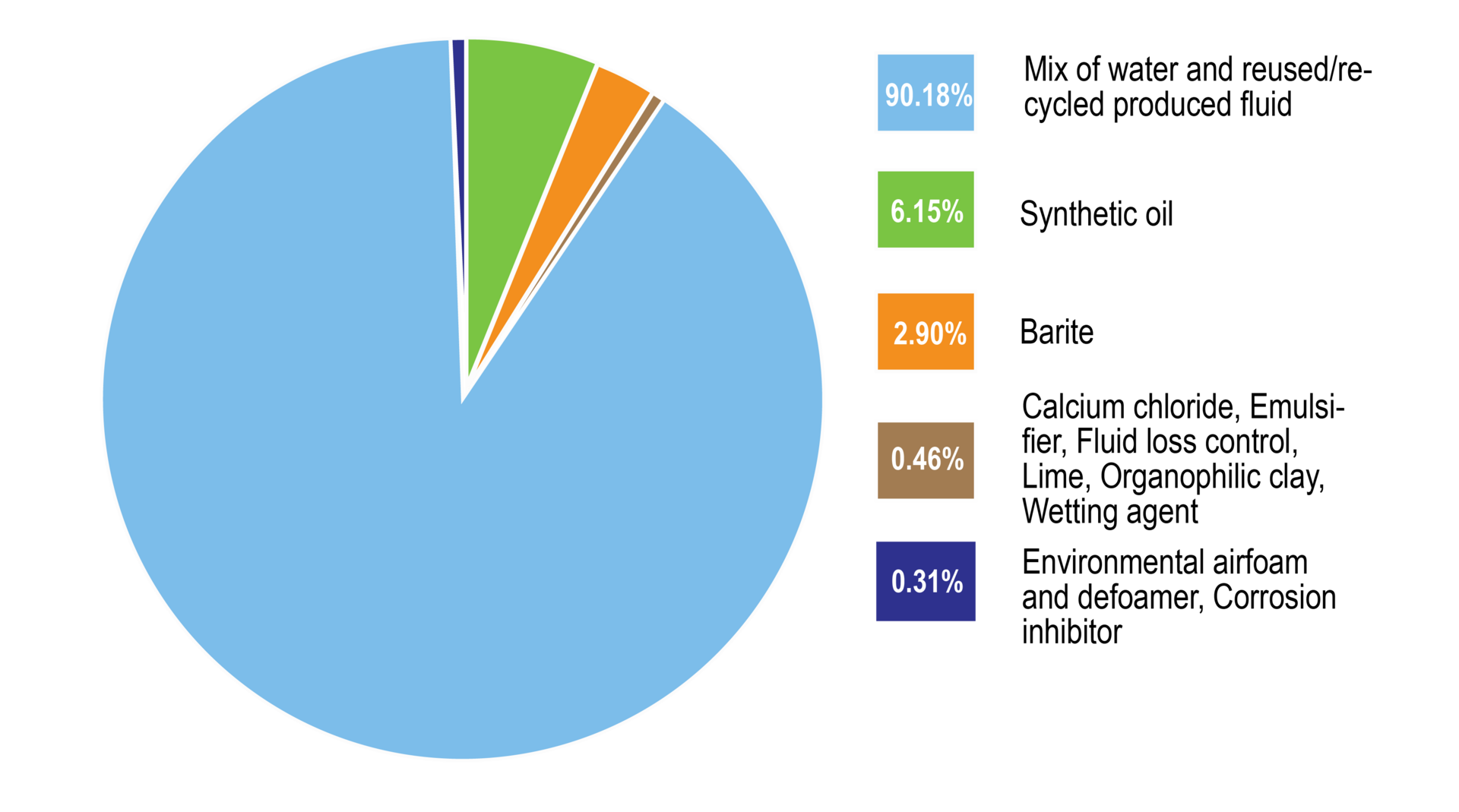

Typical Drilling Additives

The pie charts below represents a generalized breakdown of the components in typical drilling fluids for a Marcellus and Utica well. Fluids used during drilling are returned to surface and reconditioned/reused.

Marcellus Well Drilling Additives

Utica Well Drilling Additives

Commonly Used Additives, their purposes, other common uses:

Foam is utilized to condition the wellbore and help carry cuttings out of the well. Defoamer is utilized at the surface to remove foam in the solution.

Main Compound: Hydrotreated light naphenic and Hydrophobic silica

Common Use: Shampoos, detergents, cleaning products

Used to increase the weight of the drilling fluid.

Main Compound: Barium sulfate

Common Use: Filler for paper

Used to oil-wet solids such as barite.

Main Compound: Hydrotreated distillates

Common Use: Automotive fluids

Used to prevent the shale from swelling.

Main Compound: Calcium chloride

Common Use: Dust control, food service

Typical Hydraulic Fracturing Additives

The pie chart below represents a generalized breakdown of the components in a typical fracture job.

Commonly Used Additives, their purposes, other common uses:

Helps dissolve minerals and initiate cracks in the rock.

Main Compound: Diluted Hydrochloric acid

Common Use: Household cleaners, swimming pool sanitation and food production/processing

Eliminates bacteria that can cause corrosive byproducts by reacting with microorganisms that may be present in the treatment fluid and formation.

Main Compound: Often Glutaraldehyde

Common Use: Sterilization of dental and medical equipment

Prevents the corrosion of the pipe.

Main Compound: Methyl alcohol

Common Use: Pharmaceuticals, adhesives, and plastics

Reduces the effects of friction in the pipe.

Main Compound: Polyacrylamide/Mineral oil

Common Use: Water treatment, make-up remover, laxatives and food processing

Turns iron in the water soluble to help prevent precipitation of metal oxides.

Main Compound: Citric acid

Common Use: Food additive, flavoring in food and beverages, lemon juice

"Props” the cracks in the rock open as the fracturing fluid is withdrawn.

Main Compound: Proppants typically consist of different types of sand. Silica, quartz sand

Common Use: Drinking water filtration and playground sand

Helps to prevent scale buildup in the formation and in pipes by attaching itself to the formation.

Main Compound: Phosphoric acids

Common Use: Fertilizers, water treatment

Fluids utilized in the hydraulic fracturing process are returned to surface, along with other produced fluids and recycled/reused as base fluid/water for future subsequent wells. This significantly reduces the demand for freshwater across our operating footprint.